Defending the Cable Tie in Solar Applications

.jpg?sfvrsn=0)

Defending the Cable Tie in Solar Applications

By Brent Brucker, Head of Strategic Sales & Key Accounts, Sales

Sitting on the wire-management side of the solar industry gives me a unique perspective. Everyone agrees that the decisions made on this subject are important. But the time, effort and real thinking that go into those decisions vary dramatically.Decisions made at all levels of this industry are important. It’s the lower-dollar-value decisions that get short shrift here. I get it.

In the last half decade, I’ve seen shifts in this segment of the solar market – some good, some bad.

Owners and asset managers have seen firsthand the consequences of poor decisions. It doesn’t take long for a poorly designed wire management system to fail, couple of years, sometimes less.

Here's some good reading.

Case Study - 10 years later, “Solar Ties” stand the test of time

Read More

Take a tough environment with temperature extremes, constant irradiation (that’s why the system is there right?), wind, etc. Then toss in a little tracker motion, and you have a great recipe for unexpected remediation. That rework seems to have gotten under a lot of developers’ skins as the proliferation of wire management specification for EPCs to follow has flooded the market.

It’s these specifications, done for the right reasons I’m sure, that I’d like to discuss.

Most common guidance is something like, “no cable ties shall be used to support cable” and “use metal-core wire management devices only for support of PV cables.”

We assume that most of the time we see these stipulations, somebody got burned. They acquired or assumed day-to-day control of a PV farm and quickly realized an unwelcome expense to keep the cables out of the dirt. “Not gonna do that again,” echoed around the room and in came metal and coated metal to the rescue.

The good news: somebody recognized the importance of proper wire management and turned the ship in the right direction.

Now, here is the problem. And yes, I say this as a person who sells both plastic and metal parts: most parts are fine when correctly applied. But to understand what that means requires, you guessed it, time, effort and real thinking.

Put anything made of plastic through or near sharp metal, it is toast. Same for a coated metal part.

Remember that tracker moving back and forth, kind of like a saw? Do you know what that metal part or coated steel cable is going to do over time? No, you don’t because none of us do.

The metal is probably going to be around for the life of your system. But what happens if it wears through the conductor jacket? Are you going to know there is a problem? What material is your plastic? What about your metal? Is it suitable for what you are about to put it through? Are you sure?

So, how do you know the health of your PV farm’s wire management system? If the cables are secured with metal or coated metal, you need get out of the Gator and inspect every one of your half-million wire management devices. Missing cable damage can lead to serious issues including arcs and fires and other exciting things. The industry is starting to see these issues.

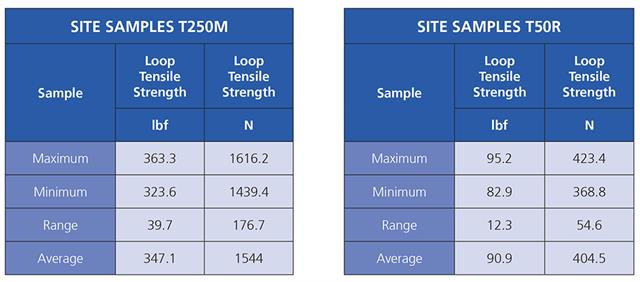

This article has the term “cable tie” in it, so let’s get to that part. I just revisited a 12-year-old solar site in Southern California where our team pulled samples of our original solar offerings (older version of material) and tested strength on them. They were, in fact, stronger than the day they were sold.

This article has the term “cable tie” in it, so let’s get to that part. I just revisited a 12-year-old solar site in Southern California where our team pulled samples of our original solar offerings (older version of material) and tested strength on them. They were, in fact, stronger than the day they were sold.

That result got us thinking. There’s nothing wrong with a cable tie – or plastic in general. It’s the misspecification of the type of plastic and the misapplication of the part that leads to problems. Really, no different than metal.

The cable tie (just one of dozens of parts we supply to the solar industry) is an engineering wonder, revered the world over for its utilitarian form and ubiquitous supply.

I can sell you a cable tie that will last 40+ years in the sun, or 10 or 15 or 20 years. You get to decide. But if you apply it incorrectly, that durability is wasted.

In other words, don’t blame the tie.

About the Author:

Brent Brucker is HellermannTyton’s Director of Strategic Sales for Electrical. Brent has had a varied career prior to joining HellermannTyton seven years ago, including working in the communications, energy efficiency, construction and solar industries. Brent’s team at HellermannTyton handles key accounts from the world’s largest solar contractors to household names. He and his wife are actively involved in animal rescue activities. If there remains free time after that work, he can be found gardening, building something in the garage (most often a motorcycle of gas or electric power) or outdoors camping – desert camping is his favorite. These days, Brent spends much of his travel days heading out to the Rust Belt to watch his son play college soccer.