- International

- Argentina

- Australia

- Austria

- Belgium

- Brazil

- Canada

- China

- Czaech Republic

- Denmark

- Finland

- France

- Germany

- Hong Kong

- Hungary

- India

- Ireland

- Italy

- Japan

- Mexico

- Netherlands

- Norway

- Philippines

- Poland

- Portugal

- Republic of Korea

- Romania

- Russian Federation

- Singapore

- Slovenia

- South Africa

- Spain

- Sweden

- Thailand

- Turkey

- UAE

- United Kingdom

- United States

Identification labels

Handwriting is Dead – When it Comes to Solar Labels

I often wonder about my handwriting. I used to have good penmanship. According to Google, in 2010, the practice of teaching cursive was removed from the curriculum of most schools. If I didn’t know better, I might theorize the solar inspectors might be to blame.

Hey, it’s possible. They’re always insisting on clear, readable printing and in many cases, handwritten calculations are just not accepted. And if they were, block print would be preferred over cursive.

Even if you take the time to employ your best writing technique, readability is only half the problem. If your message fades in a year, what good is it to anyone?

In some jurisdictions, it is acceptable to handwrite the many variable data voltage labels that are part of every PV system. However, it is not acceptable in most jurisdictions.

There are several reasons why. First, most AHJs are concerned that a handwritten voltage calculation may not be readable to someone else down the line. It is a valid point as many of us tend to be in a hurry or, even employing our best efforts, printing on something small makes it difficult to achieve legibility.

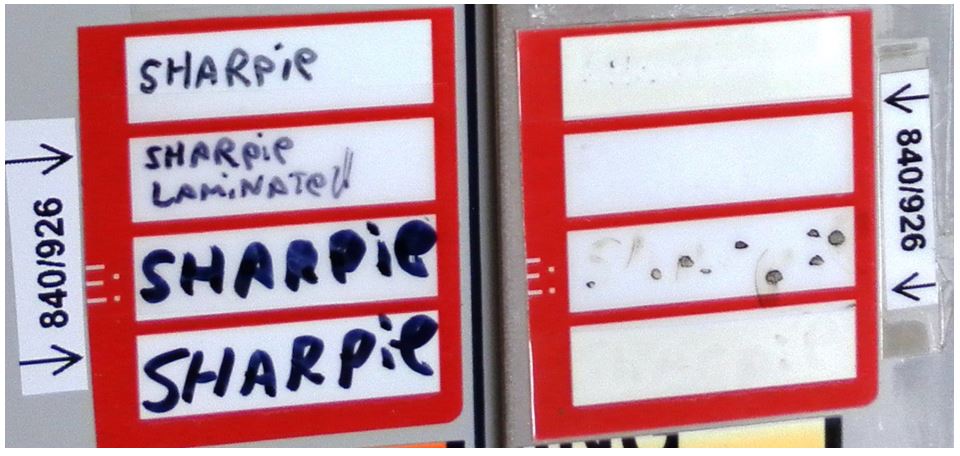

Second, handwritten markings tend to be created using a Sharpie. This popular marker may have the word “permanent” printed on the side of the pen, but Sharpies are not made with UV exposure in mind. For instance, in Figure 1, the image on the left is a label marked with a Sharpie; on the right is the same label after 1,400 hours of Xenon Arc accelerated aging.

In the real world, and exposed to sunlight, the handwriting on this label could be totally erased in as little as one to two years. Even with a clear UV laminate, the ink will still fade.

Sharpie Pens

After only 1400 hours of Xenon Arc Exposure. This is the equivalent of 2 Florida sun years of exposure. FAIL for readability.

Figure 1

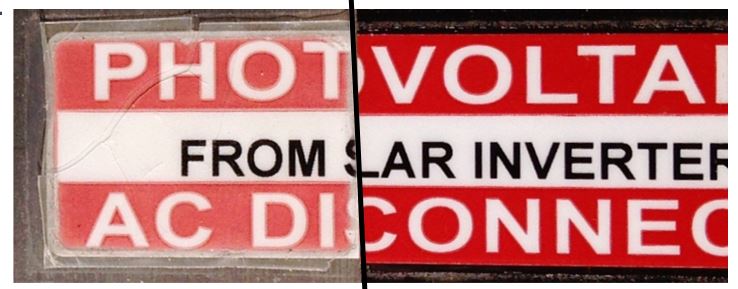

HellermannTyton Pre-Printed (Variable Print) Solar Labels

This photo shows the results of 16,206 hours - equivalent outdoor exposure using a Xenon Arc chamber. This equates to 25.97 Florida sun years of exposure.

16,206 hours exposure using the 552-clear laminate. Ink color fading. Slight edge lift and degradation of clear laminate. PASS for readability.

Figure 2

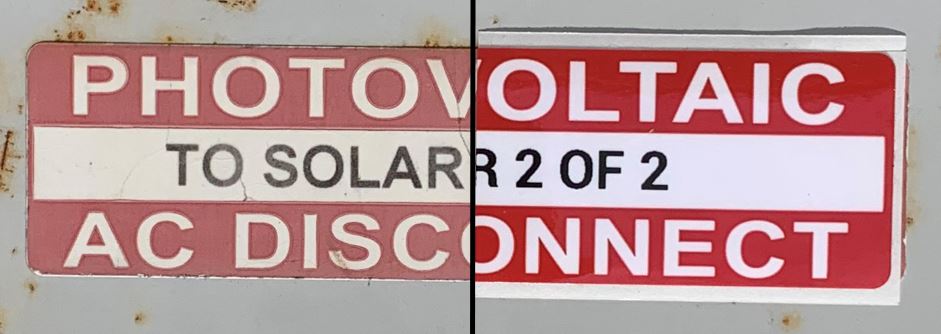

Variable Printable Solar Labels

This photo shows the results of 10 years actual outdoor exposure.

10 years exposure shows slight change in red color and no fading of thermal transfer printing. No edge lift or adhesive failure. Product is not laminated with the optional UV protective laminate.

Figure 3

Thermal Transfer: UV-Stable and Compliant

The best way to ensure durability for your printed calculations is to use a good thermal transfer printer with UV-stable inks. Such printing systems give you the ability to create almost any style or type of label that is required. In addition, these printed labels will be durable and fade resistant.

I mentioned that the “after” photo of the label in Figure 1 was taken after 1,400 hours of Xenon Arc exposure. Now, look at the thermal transfer printed label after 16,206 hours in the same Xenon Arc chamber (Figure 2). Depending on the type of test, 16,206 hours could represent over 25 Florida sun years of light.

Even without an additional laminate, thermal transfer printed inks are durable. In Figure 3, the label and printing have been exposed to actual outdoor conditions for 10 years. This photo is from a southwest facing panel in Wisconsin. As you can see, in either case – laminated with an additional UV cover, or un-laminated – the variable black printing is still visible and functional.

I may not be the Emily Post of our day when it comes to handwriting. But even if I were, it makes sense to let the machines do the work. No matter how beautiful the handwriting, no one will get the message if they can’t read it.

About HellermannTyton

HellermannTyton is a global manufacturer of cable management and identification solutions for automotive, solar, electrical, construction, industrial automation, broadband and other OEM markets. The company's integrated approach to product design, sustainability, production, quality assurance and delivery is optimized to benefit local and global customers. HellermannTyton operates in 39 countries, with North American headquarters in Milwaukee, Wisconsin. (www.hellermann.tyton.com).